GRP in Railways, by Mita

.jpg?width=2199&height=2199&ext=.jpg)

Andrew Sillars

Rail Sector Manager, Mita

Note: The opinions expressed in Products & Services do not necessarily represent the views of ECA. Unless specifically stated, goods and services mentioned in advertorials or advertisements are not formally endorsed by ECA, which does not guarantee or endorse or accept any liability for any goods and/or services featured on this website.

Having supported the specification of Glass Reinforced Polymer cable containment since 2005, I have experienced its unique features such as light weight, long-life durability, no deburring, no earth bonding and many more. All these advantages of GRP Cable Containment support a cheaper, quicker and easier-to-install system that gives a true fit-and-forget solution.

MitaR , our long standing brand which is designed and manufactured in the UK, is now powered by Wibe Group, an RISQS approved supplier. I am proud to introduce our extensive cable support offer which includes Glass Reinforced Polymer (GRP) cable ladders, trays and elevated cable troughing with accessories.

GRP elevated cable troughing is an especially useful containment system for rail. Ground Level Troughing (GLT) is often used in signalling and telecoms schemes for the cable connections to lineside equipment such as points, train detection, signals and radio sites. However, in many places, GLT cannot be used due to the ground profile and steep embankments and cuttings. GRP is an ideal alternative for such locations and it is also essential for large current-carrying power cables.

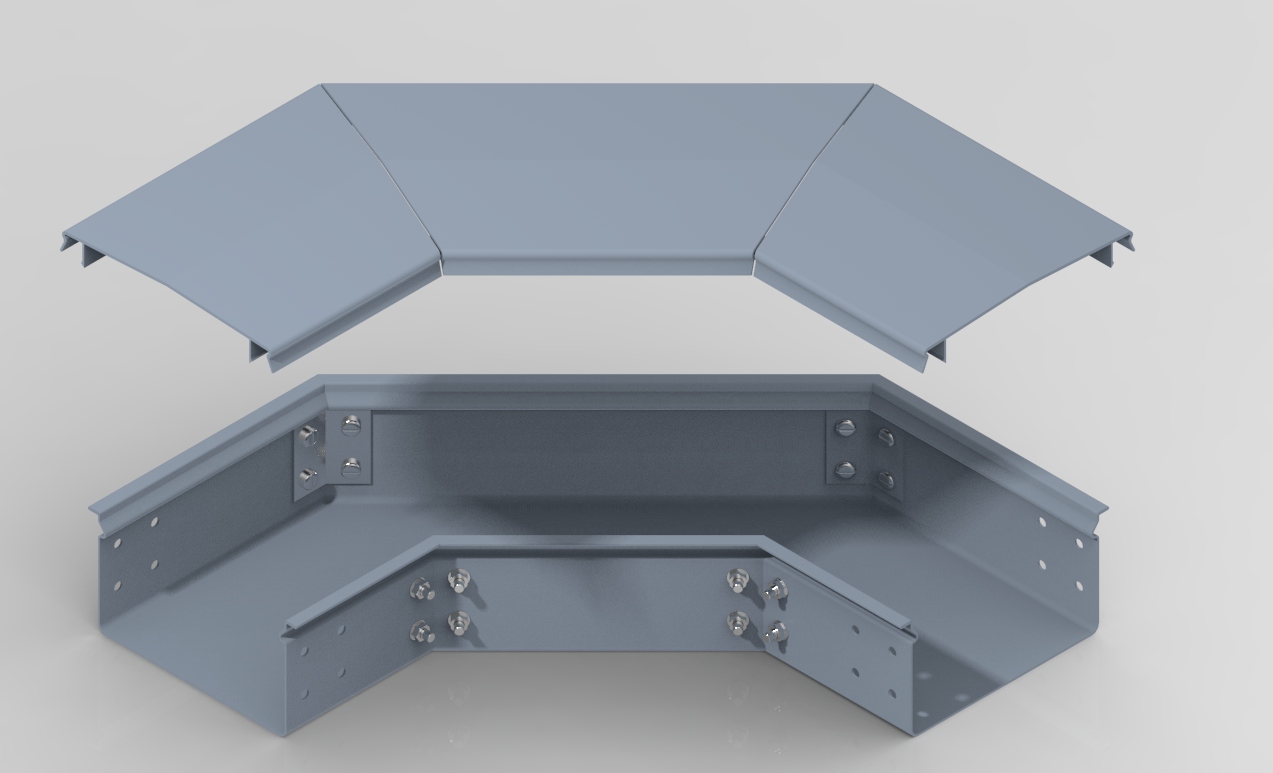

High quality manufacture

MitaR GRP is produced by pultrusion technology. This uses a combination of unidirectional and cross-strand glass mat which is resin-impregnated and pulled through a hot die to produce a very solid, structurally sound profile with excellent mechanical rigidity unlike other moulded systems. MitaR GRP does not contract or expand with heat causing the troughing route to distort. It is produced with a high quality of manufacture and modified by the use of additives to the resin, and with protection from ultra-violet light. This year, with the launch of the new GRP GMAXR 6m troughing range, which allows a 6m post span, MitaR GRP becomes a full offer with its 3m or 6m lengths to meet the needs of every application in the most cost-effective way.

Features and benefits

MitaR GRP is 70% lighter than steel; it is also corrosion resistant. It does not conduct heat and has excellent durability against adverse weather conditions. The product offers excellent UV stability resulting in a cost-effective long-term solution. Discover its advantages over steel in this article.

The MitaR GRP is provided in a wide range of trays, troughing and ladders which can support any type of cable – especially power and fibre cables which require a gentle bending radius. Unlike some competitors’ systems, MitaR elevated troughing is provided with GRP support posts to increase its durability. The troughing lids clip securely in place, providing cable theft protection. Further security can easily be added by installing stainless steel bands around the elevated route.

Working with GRP

Another particularly useful feature of the MitaR GRP system is that it is integrated with the Bentley Raceway and Cable Management Building Information Modelling (BIM) tool.This provides a complete layout, routing and material estimating function in a single, integrated system. It can be applied from the initial concept design through to detailed design and construction. A user can create an accurate 3D model of the cable troughing route, making it easy to ensure that adequate space and clearances are available in confined locations, and for the detailed design and material requirements to be quickly and easily produced.

Network Rail approval and other applications

The MitaR GRP elevated cable route has been fully approved by Network Rail under Certificate of Acceptance PA05/00442 issued in 2015 for use in locations unsuited to GLT. The Zero Halogen Low Smoke (ZHLS) version has also been approved for use in sub-surface stations, connecting tunnels, and London Underground applications. It was a concern that sensitive signalling equipment was susceptible to contact by flakes of galvanisation from steel support systems and that DC traction cabling system might create eddy currents within troughing ladders and supports if they were metallic. MitaR GRP troughing was chosen as it is the best candidate with non-magnetic and non-conductive properties.

The cable containment system is not just used in rail, but has also been successfully employed in a wide range of industries including data centres, petro-chemical industries, water treatment, off-shore oil and gas etc.

.jpg?width=2199&height=2199&ext=.jpg)

Andrew Sillars

Rail Sector Manager, Mita

Related Articles

Unlocking the Value of Employee Wellbeing

A Beacon of Support: The Electrical Industries Charity

ECA Member and Barrow Raiders encourage next generation

Samantha Jones: Making Strides in the Electrical Industry

Electrifying the elections!

Public sector PQQs look to the CAS

The Electrical Industries Charity on managing money and debt

EuropeOn: Martin Bailey’s outlook for 2023

Recognising the amazing women in the security sector

A festival of electrification!

Why choose Private Medical Insurance?

Meet the latest updates to ElectricalOM

Q&A with Catherine Heaton

10 minutes with Martin Bailey, President of EuropeOn

Lessons from the EuropeOn General Assembly

Why buy PMI?

Social Value: an interface for the future

How can partnerships give you a competitive advantage?

Reflections on 2021

Electract attends first ECA Large Contractor Forum

Electrical Safety in the Net Zero home

Is social media the new way to plug the gender skills gap?

#NAW2021: “Undertaking an electrical apprenticeship was the best decision I ever made”

West&West Ltd: Apprentices are the future of our business

Wellbeing resources for a healthier Christmas

How Red Arrow transformed their business

The importance of Movember

Modular housing: new methods for new challenges

EDATA, ecommerce, and the pandemic

Mission: Compliance, with West & West Ltd

Managing the pressures of the electrical industry

How will electricians evolve after COVID?

Celebrating women in engineering

A second chance: employing ex-offenders

Modern offsite: Safer, faster, greener, cheaper?

Three ways to stop tool thieves in their tracks

Are you up to date with ECAtoday?

ECAtoday is the official online magazine of ECA and reaches thousands of people within the electrotechnical and engineering services industry.

Copyright © 2024 Electrical Contractors Association Ltd

.jpg?width=500&height=350&ext=.jpg)

.jpg?width=1000&height=667&ext=.jpg)